Quizzes: Can you name these 15 Clocks?

Bob

July 4, 2023

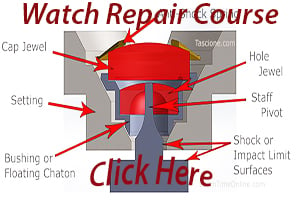

Incabloc Shock Absorber System

Bob

June 7, 2023

Try Your Luck – Quizzes!

Bob

May 26, 2023

Omega Speedmaster: The Watch That Saved Apollo 13

Bob

April 15, 2023

Can You Name These 10 Tools?

Bob

March 28, 2022

re: Todays Special Discount with Hermle Clock Course Included

Bob

February 12, 2020

Course Login and Navigation Video Tutorial

Bob

January 17, 2020

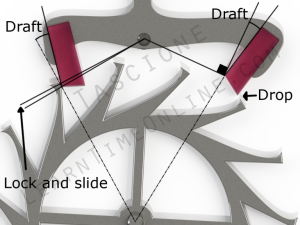

Geneva Stop Work

Bob

September 8, 2017

Hauser Pivot Polisher

Bob

November 16, 2016

MORE POSTS

COURSES