[ShowSalesProof ID=1][/ShowSalesProof]

Triple Chime Hammer Tail Repair

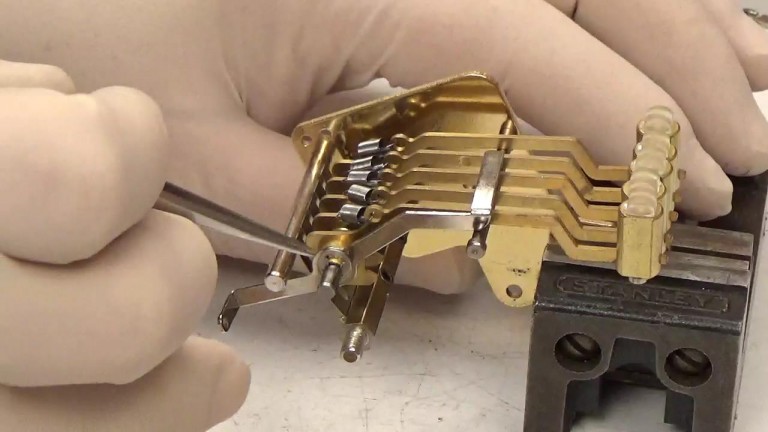

Here’s another helpful video by William covering an interesting triple chime hammer tail repair technique using a simple grinding fixture he built to fit on any watchmakers lathe. In the video he covers:- Explanation of problems resulting from worn chime hammer tails

- How to build a simple but valuable fixture to hold the hammer tail in place for accurate grinding of active surfaces

- How to do the actual grinding and polishing

- How to make adjustments for equal hammer drop

The fixture for holding the hammer is a great idea. Thanks for the post.

Thank you James, have a great day.

Nice video, I liked the part about equal adjusting of the hammers and the table you made for holding the hammers

Hi Michael, thank you for the comments. Understanding those subtle adjustments really makes it alot easier to deal with when having problems. Have a good day.

Thanks for a nice video. Good points to remember.

Thank you Amos for the kind comments., always appreciated.

Excellent informative clear video, well done William.

Thanks for sharing.

Hello William, I just noticed you comment….thank you…nice name by the way. Have fun.

Amazingly clear and informative video, totally enjoyable

Antonio, thank you for the kind comments, glad you enjoyed. Have a fantastic day!

Very good information and quality video. I can see all sort of uses for the lathe tables that William constructed.

Excellent video. I really like the table of the tool rest! Thanks for sharing.

Terrific video and the information is presented so well. It’s like I am in the room with you William. I look forward to seeing you in the next video. Thank you for the great job, Leslie

A well done session. Informative, well explained and you know that you will learn something from it. I liked the tool/workpiece rests you made for lathe work.