Automatic Winding Part 2

So how does all of this work? Well first let’s simplify the entire auto-wind mechanism by visualizing it as a stand-alone device. By treating it as an attachment or module that is in most cases just mounted to a basic watch movement which is then internally linked to those parts of the watch movement that wind the mainspring makes it much easier to study and understand.

By viewing it as an independent, separate mechanical unit we will see that it’s actually a very simple mechanism.

It’s a little like ordering a new car with either a manual or automatic transmission. Little has to be changed on the basic automobile design to use either type of transmission. It’s a mechanical ‘plug and play’ concept.

As mentioned above there are many different auto-wind designs but all serve the same purpose of capturing and then converting random wrist motion energy into torque used for winding the mainspring. This energy transfer is normally accomplished by a semicircular rotor which is free to swing about a pivot point. This pivot point is usually located in the center of the movement. There are exceptions to the centralized rotor known as micro-rotors which we will briefly cover in a moment.

The more modern auto-wind watches incorporate a rotor that can continually rotate in a clockwise or counter clockwise direction. Most of these newer mechanisms allow for winding of the mainspring while rotating in either direction by incorporating a set of reverser gears. Prior to this common centralized 360 degree rotor there was a less efficient but still good auto-wind system called a bumper. We will first cover this highly collectible bumper auto-wind.

The Omega Cal 344 (Bumper) Automatic

I will begin with the Omega 344 bumper movement for a couple of reasons. The 344 is a logical choice since it’s a good robust high quality movement. Its simple yet functional easy to understand design makes it a good introductory candidate. To be honest though, the main reason is it’s the movement used in my Omega Sea Master which is the watch I most often wear as it was made in 1952 a few months before I was born and, it’s in serious need of servicing.

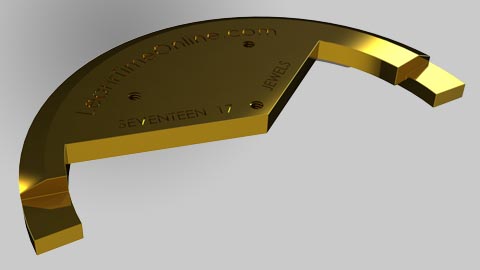

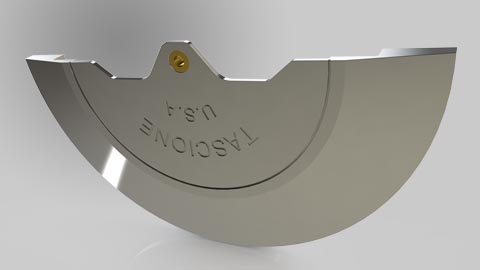

The modern bi-directional 360 degree rotor is normally a simi-circular shape. The 344 bumper rotor is also made from a near simi-circle with clearance cutouts on the top side while leaving the underside rim extending forward to engage and bounce off of stationary coiled buffer springs. Unlike the 360 degree rotor the bumper rotor swings an arc of about 120 degrees before making contact with the stop spring.

Also unlike most 360 degree systems the Omega bumper winds in one direction only. This inability for the rotor to continue its rotation beyond the 120 degrees as well as only winding in one direction of its rotation results in a less efficient autowind mechanism.

Nevertheless the bumper has become highly collectible and in most normal wear instances performs surprisingly well and its accompanying noticeable ‘thunk’ feeling when the weighted rotor makes sudden and abrupt contact with a stop spring connects the user with the timepiece in a most pleasant and satisfying manner.

For the time being we will skip past the actual disassembly of the 344 autowind mechanism since a detailed description will be covered in an upcoming, soon to be added overhaul of this watch. I’ll link to it here as soon as it’s finished. For now though you can get a good understanding of its design by diving into the interactive animation where you can remove and replace some of the winding components. Take a look at the accompanying instruction video if this is the first interactive animation you have used in this course. For now we will cover the actual functionality of the Omega bumper assembly.